Removal

• When working on the high voltage system, the work should be performed by technicians who have completed the relevant training. A lack of understanding of the high voltage system can lead to serious accidents due to electric shock or short circuit.

• When working on the high voltage system or related components, be sure to observe and be aware of the "Safety Precautions, Cautions and Warnings". If not, it may cause serious accidents due to electric shock or short circuit.

• When working on high voltage system, make sure to check the Personal Protective Equipment (PPE) and high voltage shut-off procedure.

Washer Motor

1.Disconnect the battery negative ( - ) terminal and the service interlock connector.(Refer to Battery Control System - "Auxiliary 12 V Battery - 2WD")(Refer to Battery Control System - "Auxiliary 12 V Battery - 4WD")

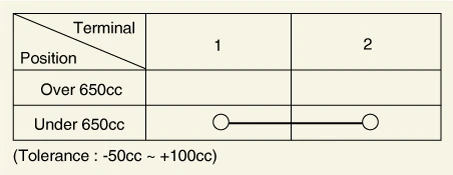

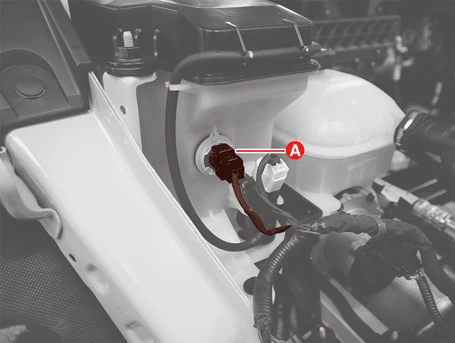

2.Disconnect the washer motor connector (A).

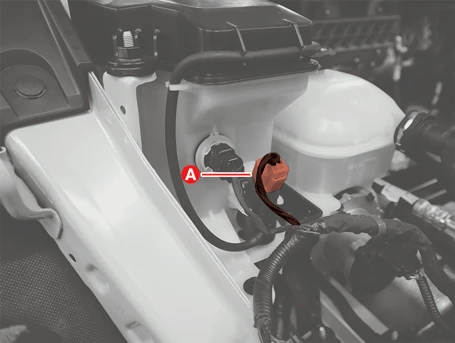

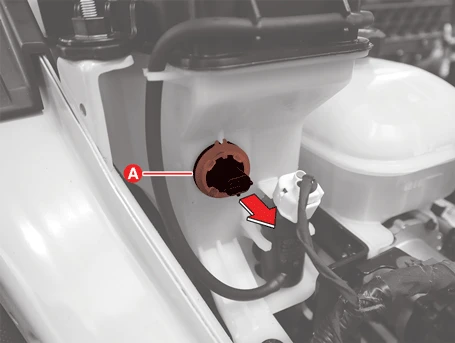

3.Remove the washer motor (A) after separating the washer nozzles (B).

Washer Fluid Level Sensor

1.Disconnect the battery negative ( - ) terminal and the service interlock connector.(Refer to Battery Control System - "Auxiliary 12 V Battery - 2WD")(Refer to Battery Control System - "Auxiliary 12 V Battery - 4WD")

2.Disconnect the washer fluid level sensor connector (A).

3.Remove the washer fluid level sensor (A).

Reservoir Tank

1.Disconnect the battery negative ( - ) terminal and the service interlock connector.(Refer to Battery Control System - "Auxiliary 12 V Battery - 2WD")(Refer to Battery Control System - "Auxiliary 12 V Battery - 4WD")

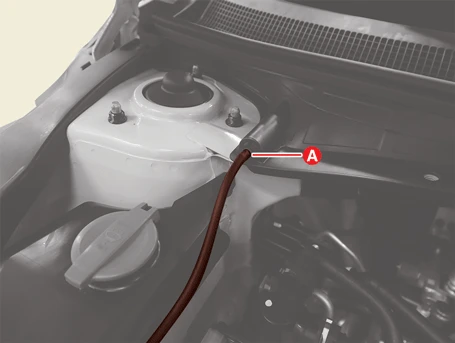

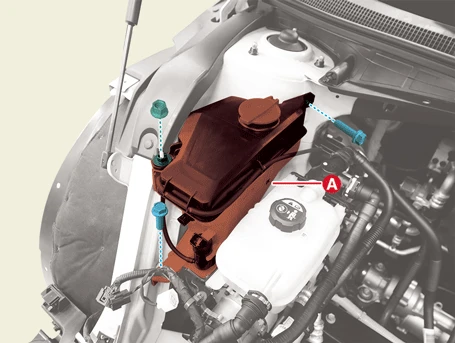

2.Remove the reservoir washer nozzles (A).

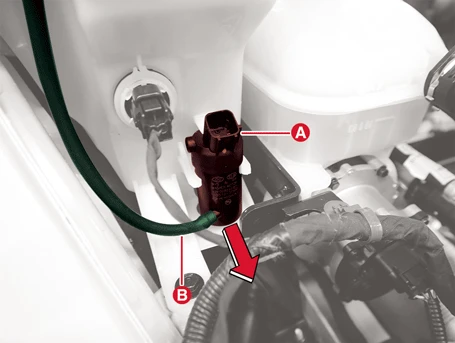

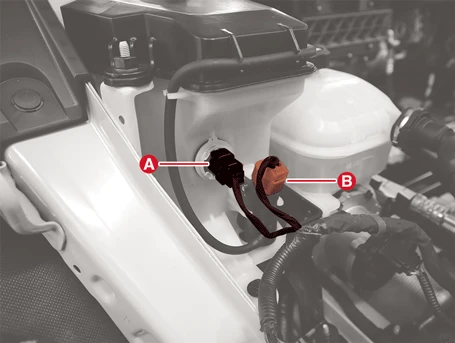

3.Remove the washer fluid level sensor connector (A) and washer motor connector (B).

4.Remove the reservoir (A) after removing the nut and bolts.

Tightening Torque :6.9 - 10.8 N·m (0.7 - 1.1 kgf·m, 5.1 - 8.0 lb·ft)

Installation

• When working on the high voltage system, the work should be performed by technicians who have completed the relevant training. A lack of understanding of the high voltage system can lead to serious accidents due to electric shock or short circuit.

• When working on the high voltage system or related components, be sure to observe and be aware of the "Safety Precautions, Cautions and Warnings". If not, it may cause serious accidents due to electric shock or short circuit.

• When working on high voltage system, make sure to check the Personal Protective Equipment (PPE) and high voltage shut-off procedure.

1.Install in the reverse order of removal.

Inspection

• When working on the high voltage system, the work should be performed by technicians who have completed the relevant training. A lack of understanding of the high voltage system can lead to serious accidents due to electric shock or short circuit.

• When working on the high voltage system or related components, be sure to observe and be aware of the "Safety Precautions, Cautions and Warnings". If not, it may cause serious accidents due to electric shock or short circuit.

• When working on high voltage system, make sure to check the Personal Protective Equipment (PPE) and high voltage shut-off procedure.

Washer Motor

1.Disconnect the battery negative ( - ) terminal and the service interlock connector.(Refer to Battery Control System - "Auxiliary 12 V Battery - 2WD")(Refer to Battery Control System - "Auxiliary 12 V Battery - 4WD")

2.Before filling the reservoir tank with water, check the filter for foreign material or contamination.→ if necessary, clean the filter.

3.Fill the washer fluid after installing the washer motor in the reservoir tank.

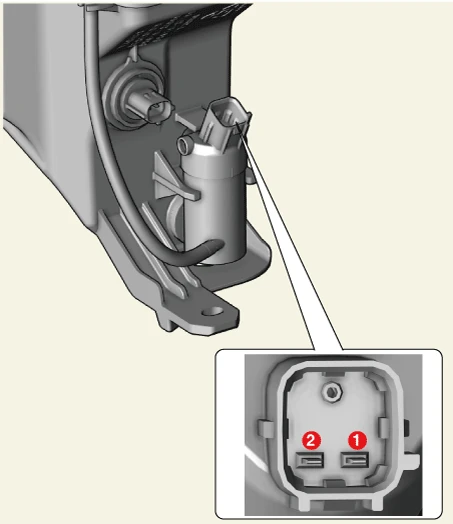

4.Connect positive (+) battery cables to terminal 2 and negative (-) battery cables to terminal 1 respectively.

5.Check that the motor operates normally and the washer motor runs and water sprays from the front nozzles.

6.If they are abnormal, replace the washer motor.

| Terminal | Function |

| 1 | Washer ( + ) |

| 2 | Ground |

Washer Fluid Level Sensor

1.Disconnect the battery negative ( - ) terminal and the service interlock connector.(Refer to Battery Control System - "Auxiliary 12 V Battery - 2WD")(Refer to Battery Control System - "Auxiliary 12 V Battery - 4WD")

2.Drain the washer fluid less than 650 cc.

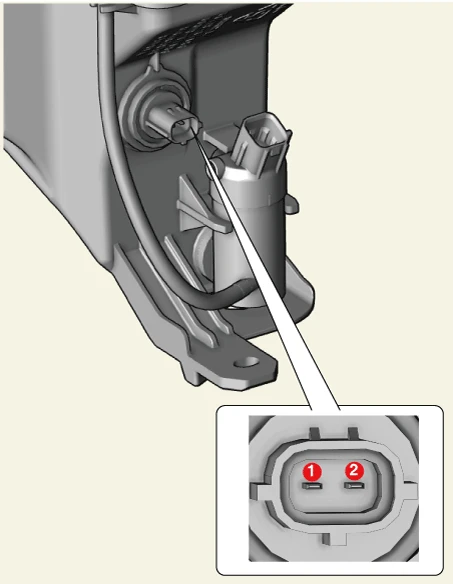

3.Check for continuity between the No. 1 and No.2 terminal in each float position.