Description

The gas/liquid of the refrigerant is separated so that only the gaseous refrigerant can flow into the compressor.Removal

• When working on high voltage system, the work should be carried by technicians who have completed the relevant training. A lack of understanding of the high voltage system can lead to serious accidents due to electric shock or electric leakage.

• When working a high voltage system, the technician must be observed and aware of "High Voltage System General Safety Information and Caution". If not, it may cause serious accidents such as electric shock or short circuit.

• When working on high voltage system, make sure to check the Personal Protective Equipment (PPE) and high voltage shut-off procedures.

1.Disconnect the battery negative ( - ) terminal and the service interlock connector.(Refer to Battery Control System - "Auxiliary 12 V Battery - 2WD")(Refer to Battery Control System - "Auxiliary 12 V Battery - 4WD")

2.Recover the refrigerant with recovery/recycling/charging equipment.(Refer to Air Conditioning - "Refrigerant Recovery/Recycling/Charging/Evacuation")

3.Remove the front trunk.(Refer to Body - "Front Trunk")

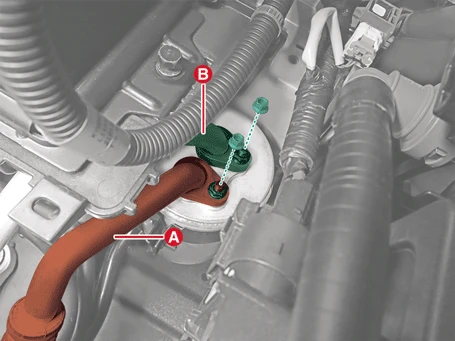

4.Separate the suction hose 1 (A) and suction hose 2 (B) after removing nuts.

Tightening torque :9.8 - 14.7 N·m (1.0 - 1.5 kgf·m, 7.2 - 10.8 lb·ft)

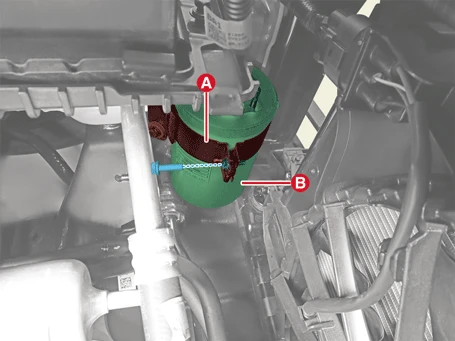

5.Remove the accumulator.

(1)Separate the accumulator bracket (A) after removing the bolt.

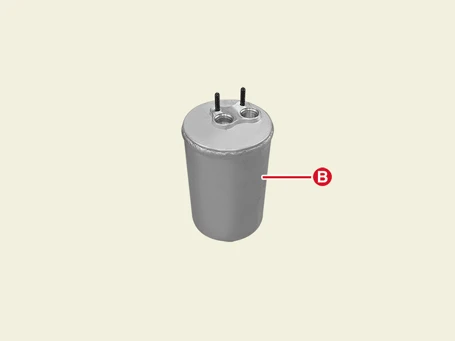

(2)Remove the accumulator (B).

Tightening torque :9.8 - 14.7 N·m (1.0 - 1.5 kgf·m, 7.2 - 10.8 lb·ft)

Installation

• When working on high voltage system, the work should be carried by technicians who have completed the relevant training. A lack of understanding of the high voltage system can lead to serious accidents due to electric shock or electric leakage.

• When working a high voltage system, the technician must be observed and aware of "High Voltage System General Safety Information and Caution". If not, it may cause serious accidents such as electric shock or short circuit.

• When working on high voltage system, make sure to check the Personal Protective Equipment (PPE) and high voltage shut-off procedures.

• es.Be sure to inject the specified refrigerant (R-1234yf) and refrigeration oil (POE) by using the refrigerant recovery/charging equipment dedicated to the electric compressor. Compressor damage and safety accidents may occur if refrigeration oil (PAG) of general vehicles is mixed.

1.Install in reverse order of removal.

• When installing a single unit, install it with the specified torque.

• Check for refrigerant leaks by using a gas leak detector.

• Charge the refrigerant after removing the air in the cooling system.

Removal

• When working on high voltage system, the work should be carried by technicians who have completed the relevant training. A lack of understanding of the high voltage system can lead to serious accidents due to electric shock or electric leakage.

• When working a high voltage system, the technician must be observed and aware of "High Voltage System General Safety Information and Caution". If not, it may cause serious accidents such as electric shock or short circuit.

• When working on high voltage system, make sure to check the Personal Protective Equipment (PPE) and high voltage shut-off procedures.

1.Disconnect the battery negative ( - ) terminal and the service interlock connector.(Refer to Battery Control System - "Auxiliary 12 V Battery - 2WD")(Refer to Battery Control System - "Auxiliary 12 V Battery - 4WD")

2.Recover the refrigerant with recovery/recycling/charging equipment.(Refer to Air Conditioning - "Refrigerant Recovery/Recycling/Charging/Evacuation")

3.Remove the front trunk.(Refer to Body - "Front Trunk")

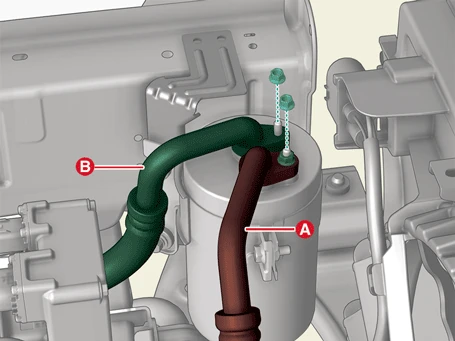

4.Separate the suction hose 1 (A) and suction hose 2 (B) after removing the nuts.

Tightening torque :9.8 - 14.7 N·m (1.0 - 1.5 kgf·m, 7.2 - 10.8 lb·ft)

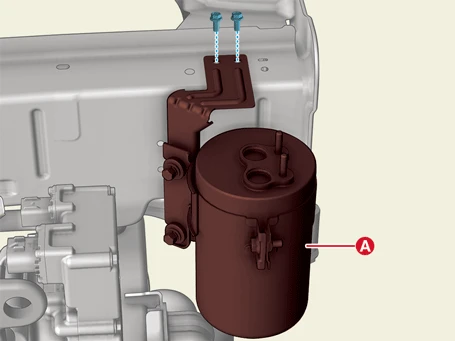

5.Remove the accumulator (A) after removing the bolts.

Tightening torque :9.8 - 14.7 N·m (1.0 - 1.5 kgf·m, 7.2 - 10.8 lb·ft)

Installation

• When working on high voltage system, the work should be carried by technicians who have completed the relevant training. A lack of understanding of the high voltage system can lead to serious accidents due to electric shock or electric leakage.

• When working a high voltage system, the technician must be observed and aware of "High Voltage System General Safety Information and Caution". If not, it may cause serious accidents such as electric shock or short circuit.

• When working on high voltage system, make sure to check the Personal Protective Equipment (PPE) and high voltage shut-off procedures.

• Be sure to inject the specified refrigerant (R-1234yf) and refrigeration oil (POE) by using the refrigerant recovery/charging equipment dedicated to the electric compressor. Compressor damage and safety accidents may occur if refrigeration oil (PAG) of general vehicles is mixed.

1.Install in reverse order of removal.

• When installing a single unit, install it with the specified torque.

• Check for refrigerant leaks by using a gas leak detector.

• Charge the refrigerant after removing the air in the cooling system.