Diagnosis Guide for Each Condition of Accident Vehicle

• The Electric Vehicle comes equipped with a high voltage battery that can cause

serious injury, like electric shocks, or even death when malfunctioning or mishandled,

so follow manual below.

• This guide is intended to provide tips for inspecting the high-voltage battery

health in relation to vehicle damage situation.

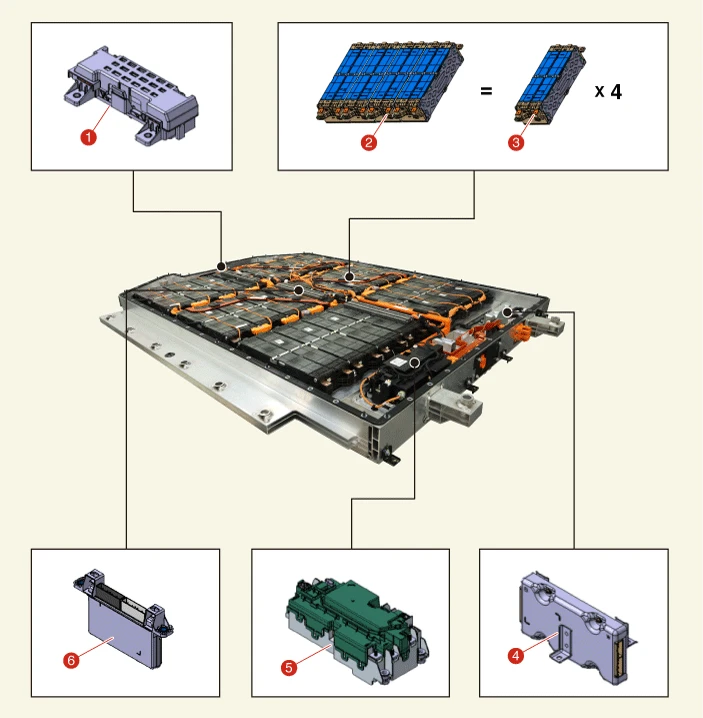

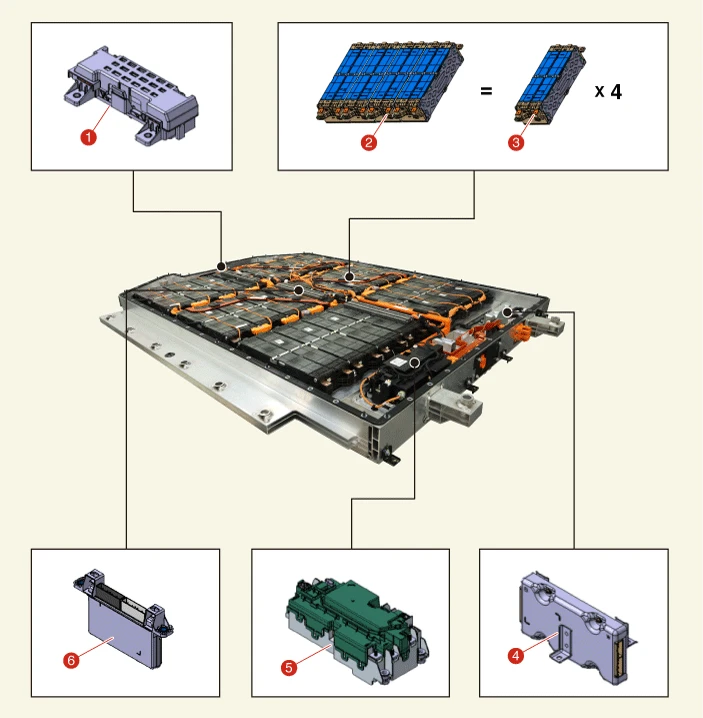

High Voltage Battery Components

Long Range Battery

Standard Battery

1. Main Fuse

2. Sub-Battery Pack Assembly (Sub-BPA)

3. Battery Module Assembly (BMA)

4. Battery Management Unit (BMU)

5. Power Relay Assembly (PRA)

6. Cell Monitoring Unit (CMU)

High Voltage Battery Inspection

The checklist to Identify high voltage battery health

|

|

Normal |

Need to Check |

Warning |

Danger |

|

Vehicles transported |

Itself |

Itself |

Itself or Towed |

Towed or Rollover |

|

Communication |

CAN communication available |

CAN communication available |

CAN communication available |

CAN communication not available |

|

Warning light |

OFF |

OFF |

ON |

ON |

|

Lower case damaged |

No damage |

Scratch |

Dent or Crack |

Dent or Crack |

|

Electrolyte leakage |

No leakage |

No leakage |

No leakage |

Leakage |

|

High voltage battery coolant leakage |

No leakage |

No leakage |

Laekage |

Laekage |

|

Noise inside high voltage battery |

No noise |

No noise |

No noise |

Noise(Tic-Tic) |

|

Temperature of the high voltage battery(module/cell) |

Normal |

Normal |

Normal |

- Sensor Data (Cell) ≥ 60°C (140°F)

- Temperature difference between modules(If CAN comm. is not possible, use

an infrared thermometer to check the surface temperature of High voltage

battery) |

Appropriate actions for each high voltage battery health condition

|

Status |

Description |

|

Normal |

| • |

All functions of high voltage battery are normal and no additional

measures are necessary. Communication for data verification

is available in this state.

|

|

|

Need to Check |

| • |

Scratches on high voltage battery lower case (protective cover)

does not affect the battery cooling system.

|

| • |

If the battery sensor data (Isolation Resistance, DTC, Module

Voltage, etc.) are normal, the replacement of a case is not

necessary.

|

| • |

If any issues are detected through the KDS, affected components

need to be replaced.

|

| • |

Battery pack air tightness test and cooling system air tightness

test need to be performed.

|

|

|

Warning |

| • |

Refer to the below procedure to check the high voltage battery

condition.

※ If any damage in the lower case is identified, replace the

lower case ASSY. However, Inner parts such as Cell Monitoring

Unit (CMU), Battery Management Unit (BMU) and modules should

be re-used.

|

|

|

Danger |

| • |

Store the vehicle in a separate space to ensure safety.

|

| • |

Avoid storing it indoors.

|

| • |

Ask professional guidance to a fire department or local high

voltage battery remanufacturing company to secure workshop safety.

|

|

The list for sensor data need to be inspected with the KDS

|

Sensor Name |

Value |

|

Isolation Resistance |

Refer to High Voltage Battery System - "Isolation Resistance Inspection" |

|

DTC ON |

NO |

|

Battery Module High Temperature |

≤ 60°C (140°F) |

|

Battery Module Low Temperature |

≤ 60°C (140°F) |

|

Battery WCS Inlet Temperature |

≤ 60°C (140°F) |

|

Battery LTR Rear Temperature |

≤ 60°C (140°F) |

|

EWP #1 Fault Status |

NO |

|

EWP #2 Fault Status |

NO |

|

BMS Heater Relay Status |

NO |

|

BMS MIL Lamp Request |

OFF |

|

OPD Active ON |

NO |

|

BMS Fault Status |

Normal |

Precautions for accident vehicle

The Electric Vehicle comes equipped with a high voltage battery that can cause serious

injury, like electric shocks, or even death when malfun ...

PREV

Vehicle long-term neglect and Refrigerant precautions

Precautions for Vehicles Left Unattended Long-term

1.Keep the Smart Key at least 2 meters (7 feet) away from the vehicle to prevent

unintende ...

NEXT