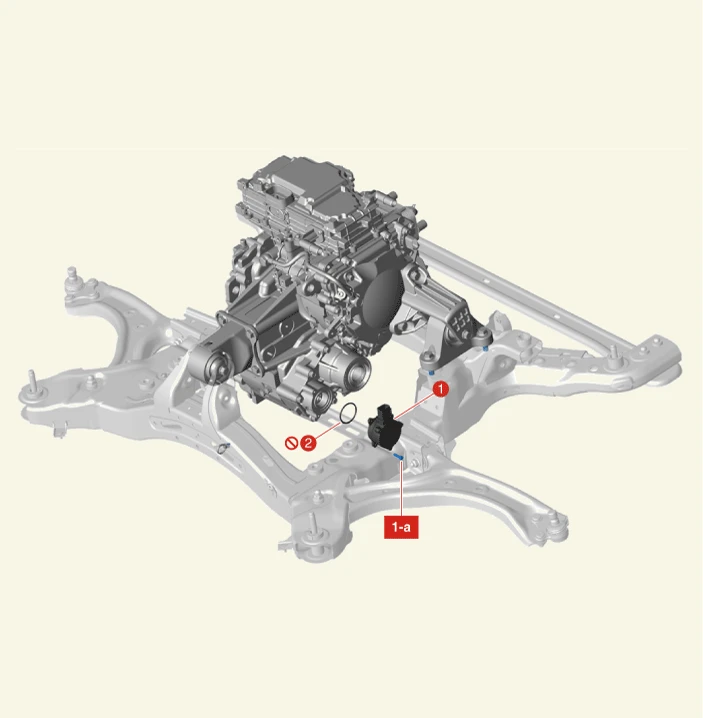

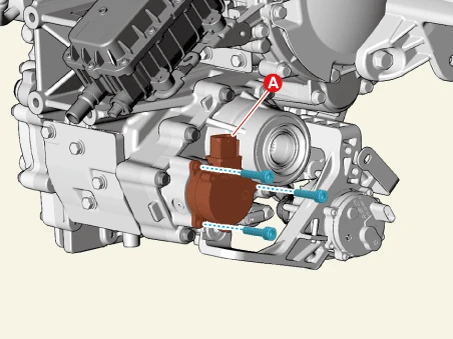

Components and Components Location

1. Disconnect Actuator System (DAS) Motor

1-a. 4.9 - 5.9 N·m (0.5 - 0.6 kgf·m, 3.6 - 4.3 lb·ft, 43.4 - 52.1 lb·in)

2. O-ring

Description

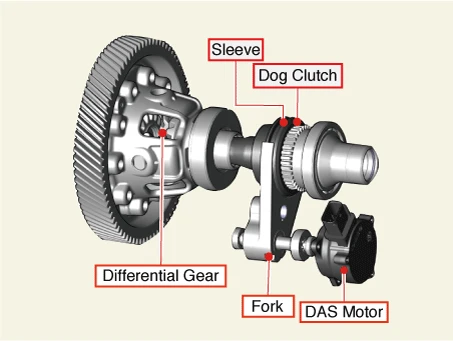

The 4WD system improves driving performance but also reduce driving range.To compensate for shortening range, 2WD drive (rear-wheel motor and decelerator drive) is applied depending on driving conditions and *DAS is applied to cut off the drive line to reduce front-wheel motor and decelerator drive line resistance.The actuator (DAS motor) installed for controlling the DAS, The DAS motor takes the VCU signal and connects or disconnects the deceleration gear and the driveshaft.*DAS : Disconnect Actuator System*VCU : Vehicle Control UnitDAS Component

DAS Motor Operating Conditions by Driving Condition

| Item | 2WD → 4WD | 4WD → 2WD | ||||

| Drive mode | SNOW, SPORT MODE |

※ If the conditions on the left are not met and the conditions below are

met

|

||||

| Rapid steering | Steering angle more than 60° , and angular acceleration 40°/sec | |||||

| Driving at gradient | Gradient more than 8% | |||||

| Vehicle speed [kph (mph)] | 15 (9.3) or slower, 120 (74.5) or faster (Normal mode only) | |||||

| The will of acceleration of the driver. | When the torque required by the driver is greater than the maximum torque of the rear wheels. | |||||

| Electronic brake actuation. | When TCS, ESC is operated |

Removal

• When working on high voltage system, the work should be performed by technicians who have completed the relevant training. It is because that lack of knowledge of the high voltage system can lead to serious accidents due to electric shock or electric leakage.

• When working on high voltage system or related system, make sure that you are familiar and comply with the "Safety Precautions, Cautions and Warnings." If you do not comply with the instructions, serious accidents due to electric shock or leakage may occur.

• When working on high voltage system, make sure to check the Personal Protective Equipment (PPE) and high voltage shut-off procedures.

1.Disconnect the battery negative ( - ) terminal and the service interlock connector.(Refer to Battery Control System - "Auxiliary 12 V Battery")

2.Remove the front under cover.(Refer to Front Motor and Reduction Gear System - "Front Under Cover")

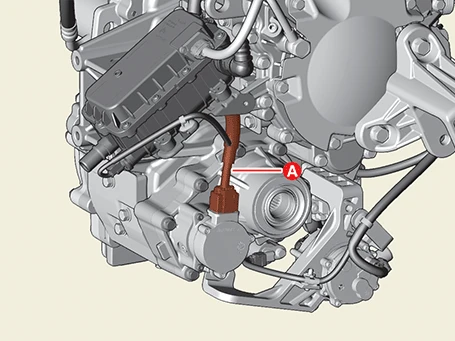

3.Disconnect the Disconnect Actuator System (DAS) motor connector (A).

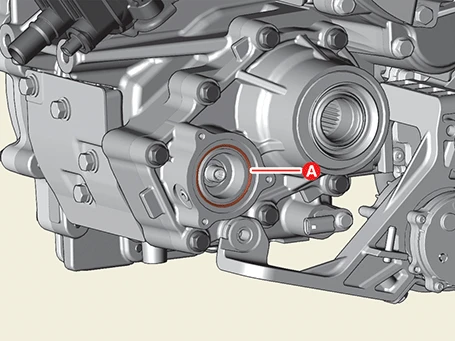

4.Remove the DAS motor (A) after removing the hexagon head bolts.

Tightening torque :4.9 - 5.9 N·m (0.5 - 0.6 kgf·m, 3.6 - 4.3 lb·ft, 43.4 - 52.1 lb·in)

Installation

• When working on high voltage system, the work should be performed by technicians who have completed the relevant training. It is because that lack of knowledge of the high voltage system can lead to serious accidents due to electric shock or electric leakage.

• When working on high voltage system or related system, make sure that you are familiar and comply with the "Safety Precautions, Cautions and Warnings." If you do not comply with the instructions, serious accidents due to electric shock or leakage may occur.

• When working on high voltage system, make sure to check the Personal Protective Equipment (PPE) and high voltage shut-off procedures.

1.Install in the reverse order of removal.