Refrigerant Recovery/Recycling/Charging/Vacuum/Leak Test

Equipped with R-1234yf recovery/recycling/charging equipment

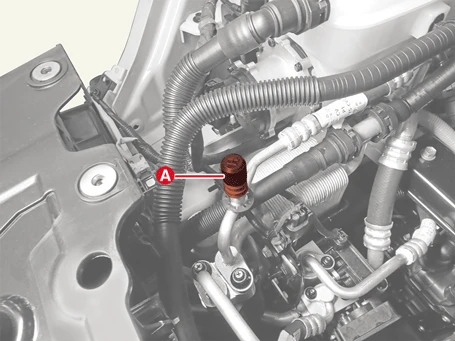

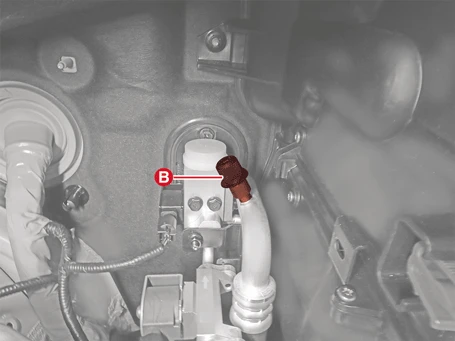

1.Connect the R-1234yf recovery/recycling/charging equipment to the high-pressure service port (A) and low-pressure service port (B) by reading the refrigerant recovery/recycling/charging equipment instruction manual.

Refrigerant recovery operation

1.With the high and low pressure valves open, the refrigerant is recovered by using R-1234yf recovery/recycling/charging equipment.

• Refrigerant recovery too quickly causes compressor oil to drain from the system.

• Refrigerant recovery must be performed with the high and low pressure valves opened. If only one valve is opened, the refrigerant recovery time increases.

2.Measure the amount of compressor oil drained from the air conditioner system after the recovery operation is completed. Supplement the compressor oil drained when charging the air conditioner refrigerant.

Refrigerant system vacuum operation

1.Perform the vacuum by using R-1234yf recovery/recycling/charging equipment while the high and low pressure valves open.

2.If the gauge remains in the vacuum zone for 10 minutes while the high and low pressure valves are opened, vacuum has been performed normally. If the pressure increases, it is a leak in the system, so repair the leak by the following order.

(1)Charging the system with refrigerant charging equipment. (Refer to Refrigerant charging)

(2)Check the refrigerant leak with leak detector and repair if leak is found. (Refer to Refrigerant leak test)

(3)Drain the refrigerant again and evacuate the system.

3.Make vacuum state by performing the refrigerant Recovery/Recycling/Charging equipment for more than 10 minutes, then close the high and low valves.

Refrigerant charge

1.Replenish the amount of discharged compressor oil by using R-1234yf recovery/recycling/charging equipment while the high pressure valve is opened after evacuating the air conditioner system.

2.Charge the refrigerant with specified amount while the high-pressure valve open by using the R-1234yf recovery/recycling/charging equipment and then close the high-pressure valve.

Regulated refrigerant amount :Heat pump : 850 ± 25 (29.98 ± 0.88)Non heat pump : 750 ± 25 (26.45 ± 0.88)

3.Check that the refrigerant is not leaking from the system with leak detector. (Refer to refrigerant leak test)

Leak test of refrigerant

When the refrigerant leak is suspected or the connection part is disassembled or loosened, perform the leak test with an electronic leak detector.1.Check the torque of the connection part, and if it is too loose, check the gas leak with leak detector after tightening it with the tightening torque.

2.If leakage continues even after re-tightening the connection part, drain the refrigerant and separate the connection part to check the contact surface for damage. If there is even a small damage, replace it with a new one.

3.Check the compressor oil and add oil if necessary.

4.Charging the system and check for gas leakage. If there is no problem, evacuate the system before charging.