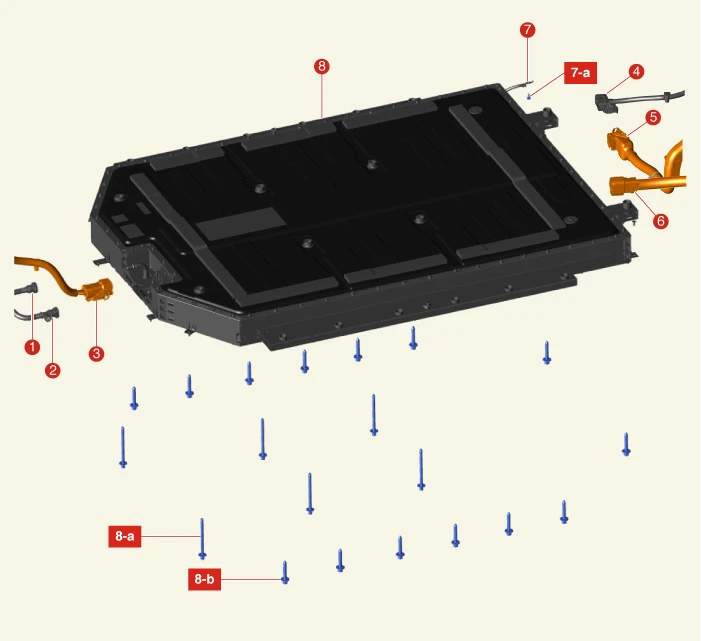

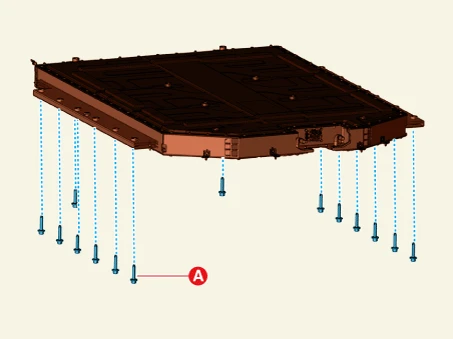

Component Location

1. Battery Outlet Cooling Hose

2. Battery Inlet Cooling Hose

3. Front High Voltage Junction Box Power Cable

4. Battery Management Unit (BMU) Connector

5. Rear High Voltage Junction Box Power Cable

6. Integrated Charging Control Unit (ICCU) Power Cable

7. Ground Cable

7-a. 7.8 - 11.8 N·m (0.8 - 1.2 kgf·m, 5.8 - 8.7 lb·ft)

8. Battery System Assembly (BSA)

8-a. 68.6 - 88.3 N·m (7.0 - 9.0 kgf·m, 50.6 - 65.1 lb·ft)

8-b. 117.7 - 137.3 N·m (12.0 - 14.0 kgf·m, 86.8 - 101.3 lb·ft)

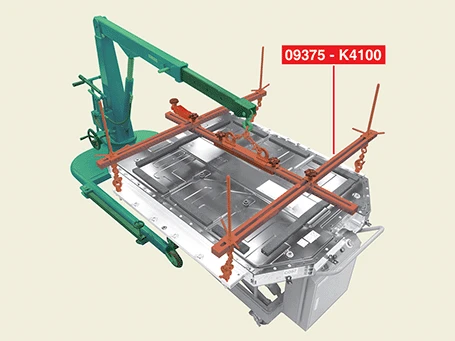

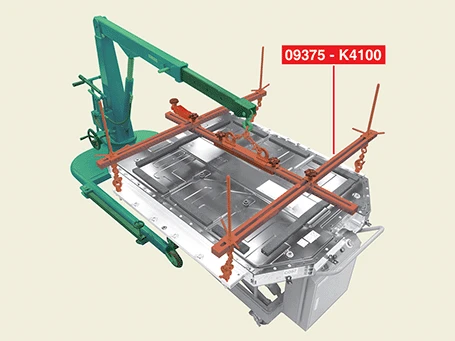

Special Service Tool

| Tool Name / Number | Illustration | Description |

|

High Voltage Battery System Assembly (BSA) transport hanger 09375 - K4100 |

|

Used for transporting the high voltage Battery System Assembly (BSA) |

Removal

• When working on high voltage system, the work should be performed by technicians who have completed the relevant training. A lack of understanding of the high voltage system can lead to serious accidents due to electric shock or electric leakage.

• When working on high voltage system or related components, make sure that you are familiar and comply with the "Safety Precautions, Cautions and Warnings." If you do not comply with the instructions, serious accidents due to electric shock or leakage may occur.

• When working on high voltage system, make sure to check the Personal Protective Equipment (PPE) and high voltage shut-off procedures.

1.Shut off the high voltage circuit.(Refer to Battery Control System (Standard) - “High Voltage Shut-off Procedure”)

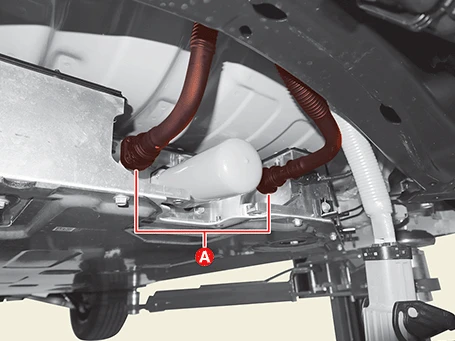

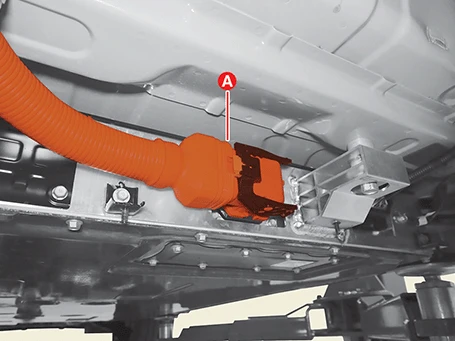

2.Separate the high voltage battery system coolant hoses (A).

• Block the high voltage battery connector by using isolation cover to prevent entering the coolant.

• Collect coolant using a clean beaker (be careful not to mix other mixtures with coolant).

• When the coolant enters the high voltage connector, make sure to clean it and then connect the connector.

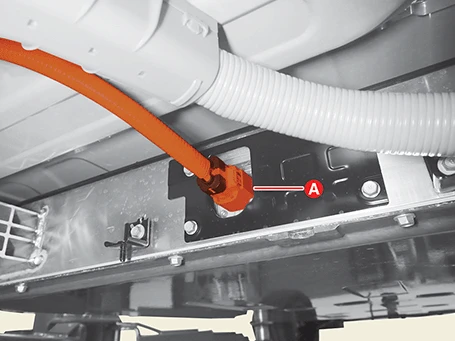

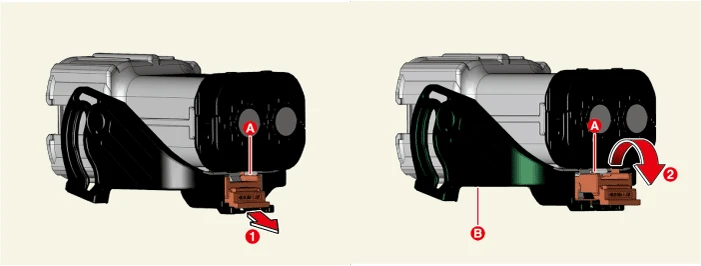

3.Disconnect the Integrated Charge Control Unit (ICCU) connector (A).

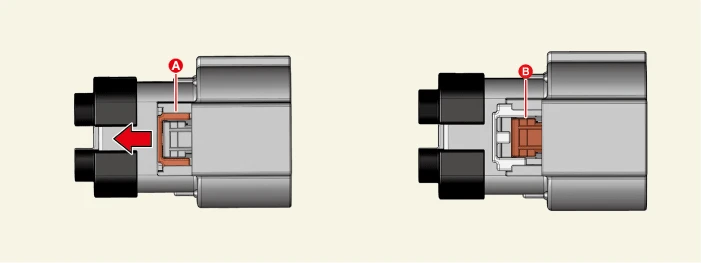

1)Release the locking clip (A) by pulling it.

2)Disconnect the connector while pressing the locking clip (B).

4.Disconnect the rear high voltage junction box power cable (A).

1)Release the locking clip (A) by pulling it.

2)Disconnect the connector by pushing the lever (A) in the direction of the arrow while pressing the locking clip (B).

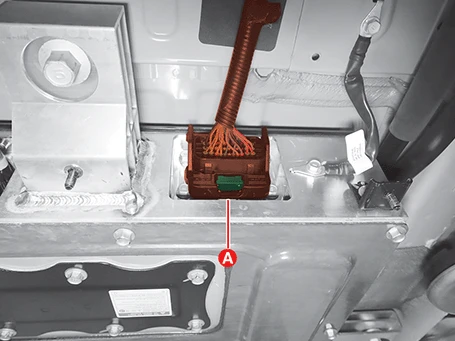

5.Disconnect the Battery Management Unit (BMU) connector (A).

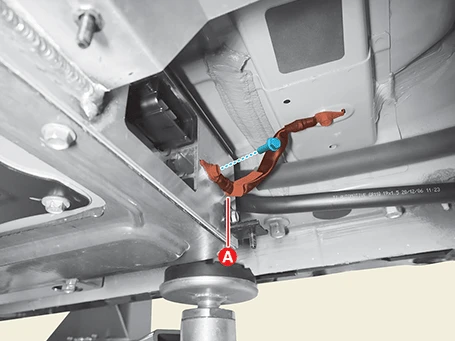

6.Remove the battery system assembly (BSA) ground cable (A) after removing the bolt.

Tightening torque :7.8 - 11.8 N·m (0.8 - 1.2 kgf·m, 5.8 - 8.7 lb·ft)

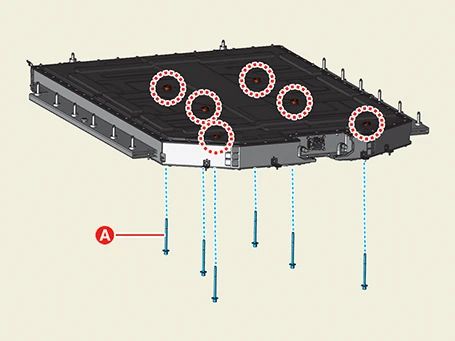

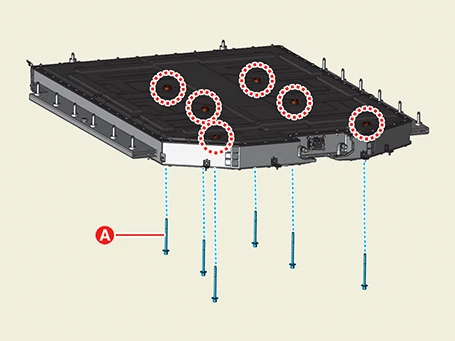

7.Remove the BSA through bolts (A).

Tightening torque :68.6 - 88.3 N·m (7.0 - 9.0 kgf·m, 50.6 - 65.1 lb·ft)

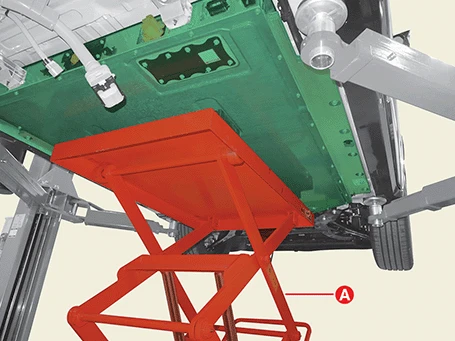

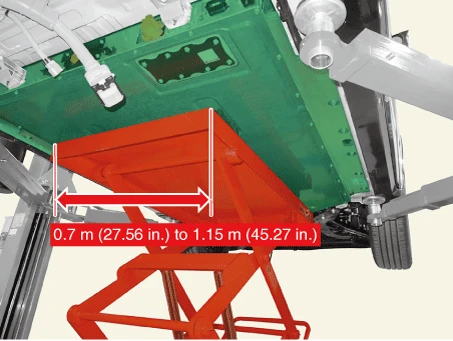

8.Support the BSA using the lift (A).

• Place an insulating mat (or rubber mat) on the lift and remove the battery. If there is foreign substance in the lower protection case, the protection case may be broken due to the battery load, but damage to the battery can be prevented with the insulating mat (or rubber mat).

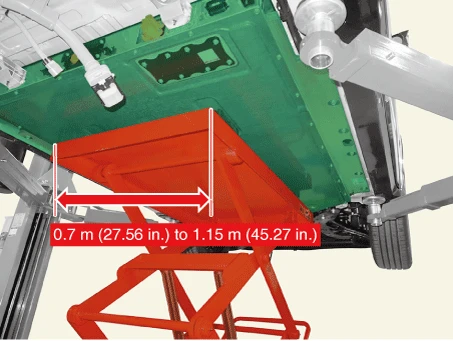

• Use a lift with a permissible payload of 700 kg (1543.23 lb) or above and a width of 0.7 m (27.56 in.) to 1.15 m (45.27 in.).

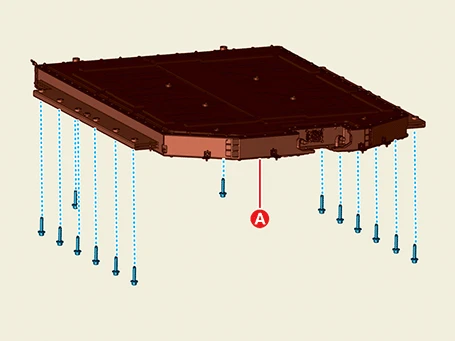

9.Remove the BSA (A) by lowering the jack slowly after removing the bolts.

Tightening torque :117.7 - 137.3 N·m (12.0 - 14.0 kgf·m, 86.8 - 101.3 lb·ft)

10.Transfer the BSA after installing the SST (09375 - K4100), then using the crane jack.

• Do not lift the BSA too much.

• Be careful not to rotate the BSA while it is lifted.

• When moving the BSA, move it on the lift and then lift it using a crane jack.

• Put the BSA on the flat insulated mat or pallets to prevent the damage.

Special Service Tool

| Tool Name / Number | Illustration | Description |

|

High Voltage Battery System Assembly (BSA) transport hanger 09375 - K4100 |

|

Used for transporting the high voltage Battery System Assembly (BSA) |

Installation

• When working on high voltage system, the work should be performed by technicians who have completed the relevant training. A lack of understanding of the high voltage system can lead to serious accidents due to electric shock or electric leakage.

• When working on high voltage system or related components, make sure that you are familiar and comply with the "Safety Precautions, Cautions and Warnings." If you do not comply with the instructions, serious accidents due to electric shock or leakage may occur.

• When working on high voltage system, make sure to check the Personal Protective Equipment (PPE) and high voltage shut-off procedures.

1.Put the Battery System Assembly (BSA) on the lift by using the SST (09375 - K4100) and crane jack.

• Place an insulating mat (or rubber mat) on the lift and remove the battery. If there is foreign substance in the lower protection case, the protection case may be broken due to the battery load, but damage to the battery can be prevented with the insulating mat (or rubber mat).

• Use a lift with a permissible payload of 700 kg (1543.23 lb) or above and a width of 0.7 m (27.56 in.) to 1.15 m (45.27 in.).

• Do not lift the BSA too much.

• Be careful not to rotate the BSA while it is lifted.

• Lift the BSA with the crane jack and place the lift under the BSA. (Do not move the crane jack)

2.Install in the reverse order of removal.

• Install the Battery System Assembly (BSA) to the specified torque.

• If the BSA is dropped, it may cause internal damage. (Do not reuse)

• The existing BSA bolts (A) should be replaced with new ones. (Do not reuse)

3.Refill battery system coolant.(Refer to Cooling System - "Battery Coolant")

4.Perform the SOC calibration with the KDS.(S/W management → Battery Management System (BMS) → SOC Calibration)