Removal

• When working on high voltage system, the work should be performed by technicians who have completed the relevant training. It is because that lack of knowledge of the high voltage system can lead to serious accidents due to electric shock or electric leakage.

• When working a high voltage system, the technician must be recognized and observe "General Safety Information and Caution". If do not follow, serious accidents like electric shock and short circuit are caused.

• When working on high voltage system, make sure to check the Personal Protective Equipment (PPE) and high voltage shut-off procedures.

• Use a fender cover to protect the painted surface.

• Be careful not to damage the connector when disconnecting.

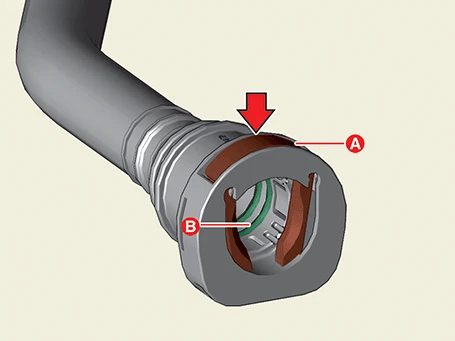

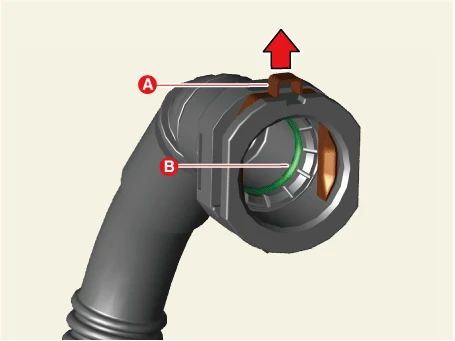

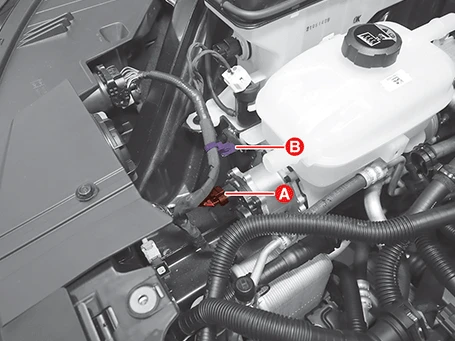

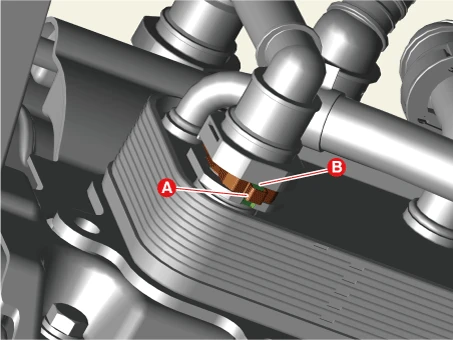

• When disconnecting a quick connector, refer to the following according to the type of quick connector.[Type A]- Remove the while pressing the quick connector clamp (A) in the direction of the arrow.- Do not touch the rubber seal (B) inside the hose.

1.Disconnect the battery negative ( - ) terminal and the service interlock connector.(Refer to Battery Control System - "Auxiliary 12 V Battery")

2.Remove the front trunk.(Refer to Body - "Front Trunk")

3.Drain the coolant.(Refer to Electric Vehicle Cooling System - "Coolant")

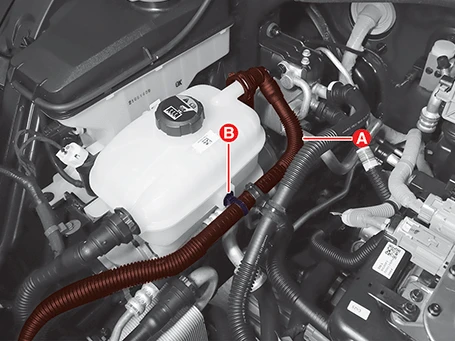

4.Disconnect the motor radiator upper hose (A) and remove the clip (B) after removing the quick connector.

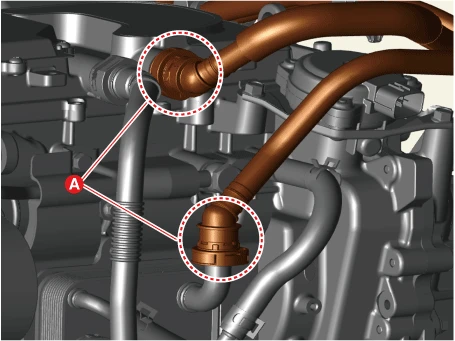

5.Disconnect the high-voltage battery radiator upper hose (A) after releasing the quick connector.

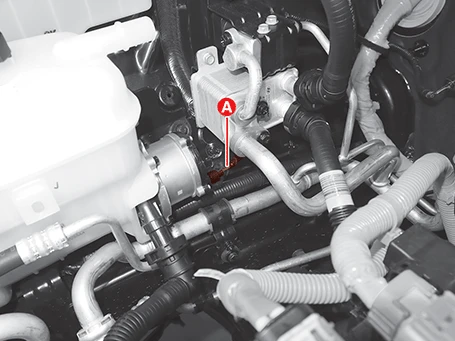

6.Disconnect the high-voltage battery EWP connector (A) and remove the wiring clip (B).

7.Disconnect the motor EWP connector (A).

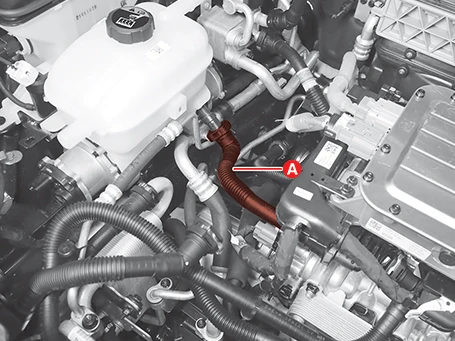

8.Remove the motor EWP inlet hose (A) after releasing the quick connector.

9.Remove the wheels and tires.(Refer to Suspension System - "Wheel")

10.Remove the front wheel guard.(Refer to Body - "Front Wheel Guard")

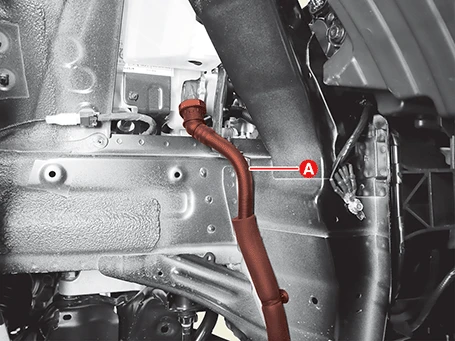

11.Disconnect the high-voltage battery EWP hose (A) after releasing the quick connector.

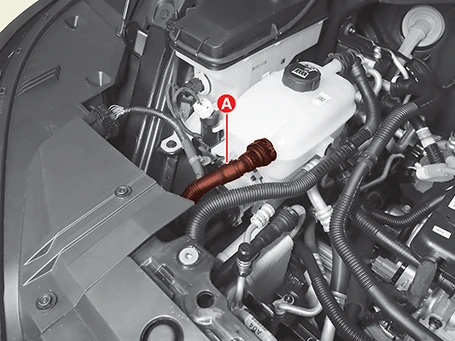

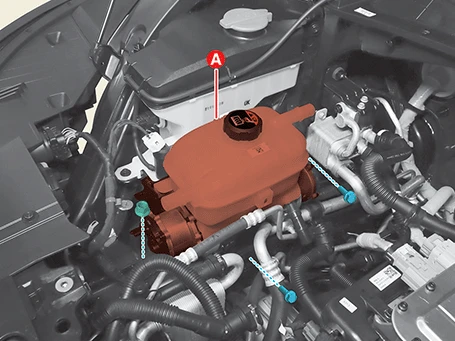

12.Rremove the reservoir tank (A) after removing the bolts and nut.

Tightening torque :7.8 - 11.8 N·m (0.8 - 1.2 kgf·m, 5.8 - 8.7 lb·ft)

13.Remove the motor electric water pump (EWP) and battery EWP.(Refer to Cooling System - "Electric Water Pump (EWP)")

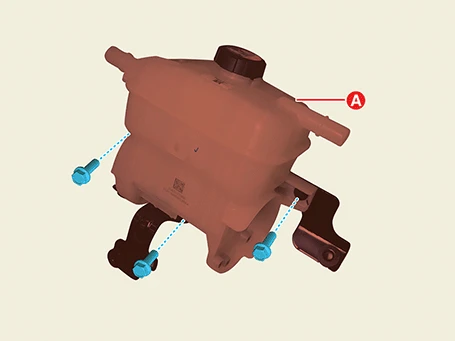

14.Remove the reservoir tank (A) from the reservoir tank bracket after removing the bolts.

Tightening torque :7.8 - 11.8 N·m (0.8 - 1.2 kgf·m, 5.8 - 8.7 lb·ft)

Installation

1.Install in the reverse order of removal.

2.Fill with coolant.(Refer to Electric Vehicle Cooling System - "Coolant")